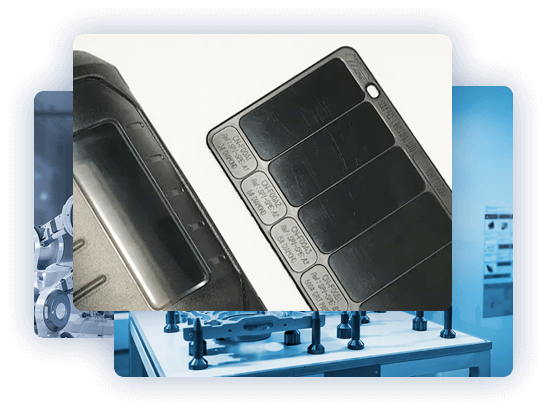

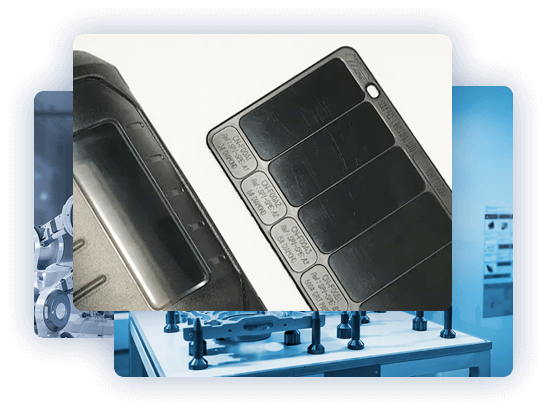

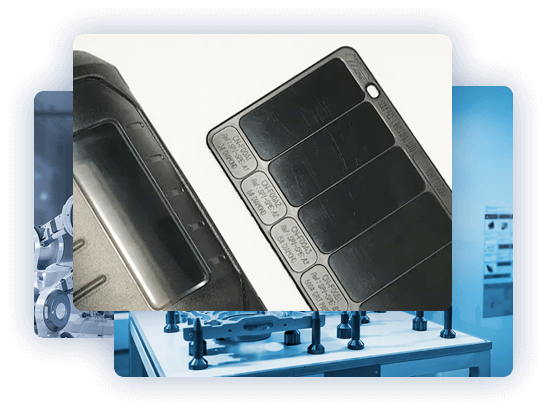

Enhance Your Rubber and Plastic Parts with Custom Surface Finishes

What Is Surface Finishing

Surface finish is a crucial aspect of successful part design in custom rubber and plastic parts. The right surface finish not only improves the look and feel of the product but also plays a role in its functionality. It can provide the desired texture, reduce friction, enhance grip, and even impact properties like wear resistance and chemical resistance.

At Zhongren, we understand the importance of achieving the right surface finish to enhance the overall quality and perception of your parts. Whether you prefer a smooth, glossy finish or a textured surface, we have the expertise to deliver exceptional results.

Custom Surface Finishing

VID 3400

VDI 3400 Surface Finish, also known as VDI surface finish, is an industry standard for achieving specific surface textures on injection molds. Established by the Society of German Engineers (VDI), it provides guidelines for consistent and reliable surface finishes. The VDI 3400 standard is widely adopted through methods like Electrical Discharge Machining (EDM) during mold machining.

SPI

The SPI (Society of the Plastics Industry) has developed a set of surface finish standards that are widely recognized in the industry. The SPI standard consists of grades from A1 to D3, each representing a different level of surface roughness and appearance.

Grade A1: The smoothest finish with no visible surface imperfections. Suitable for products requiring a high level of aesthetic appeal.

Grade B2: A fine-textured finish with minimal surface imperfections. Ideal for parts that require good surface quality but may not demand the highest level of aesthetics.

Grade C3: A moderately textured finish with visible surface imperfections. Suitable for functional parts that do not require a smooth appearance.

Grade D3: A rougher texture with more pronounced surface imperfections. Typically used for parts where surface appearance is not a primary concern.

Mold-Tech

Mold-Tech is divided into four series: A, B, C, and D. Mold-Tech Series A finishes are most widely utilised on products because they include a spectrum of fine to coarse matte finishes that do not need a laser, masked chemical etching, or other designed texturing procedures

Surface Finishing Comparison

Here's a comparison chart highlighting the differences between SPI, VDI, and Mold-Tech surface finish standards:

Surface Finish Standard

Classification

Main Focus

Typical Applications

Benefits

SPI

Grades A1-D3

Plastic parts

Aesthetics, surface quality

Offers smooth, textured, or rough finishes

VDI

VDI texture classification

Mold textures

Toolmaking, injection molding

Provides a range of surface finishes achieved through EDM or traditional texturing methods

Mold-Tech

Various textures (e.g., leather grain, geometric patterns)

Plastic and rubber parts

Enhanced visual appeal and tactile experience

Surface Finishing Example